When the Stock Level is lower than its Safety Stock, system can assist Procurement staff for planning replenishment.

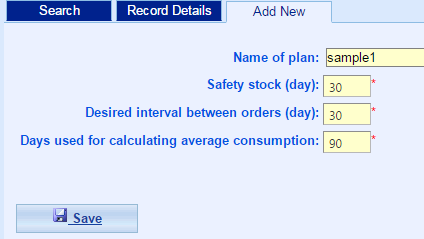

Fields |

Explanation |

Name of plan |

The name of Replenishment Plan |

Safety stock (day) |

The minimum day(s) between pending purchase orders and receiving goods to prevent stock-out. |

Desired interval between orders (day) |

The desired time interval between each purchase orders. |

Days used for calculating average consumption |

MOSES will calculate the average consumption according to record history. This field, and hence, is used to forecast the days (which you determine in here) of average consumption. |

Round qty in PO to |

The minimum quantity unit in which system will rounded up to. For example, if you set "Round qty in PO to 100", and the recommended qty is 5342 in Replenishment Plan, the quantity in PO will be 5400. |

Remark |

Remark |

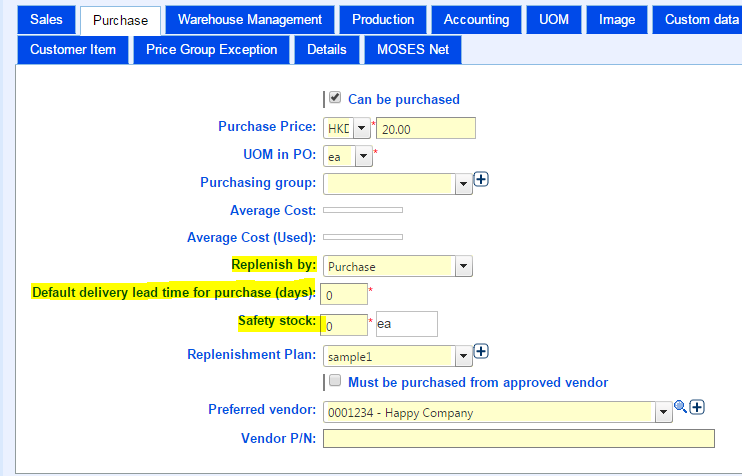

Delivery lead time for purchase (days) |

The delivery time for PO |

Safety stock |

The minimum stock to buffer between pending purchase orders and receiving goods to prevent stock-out. |